Freeze dry technology

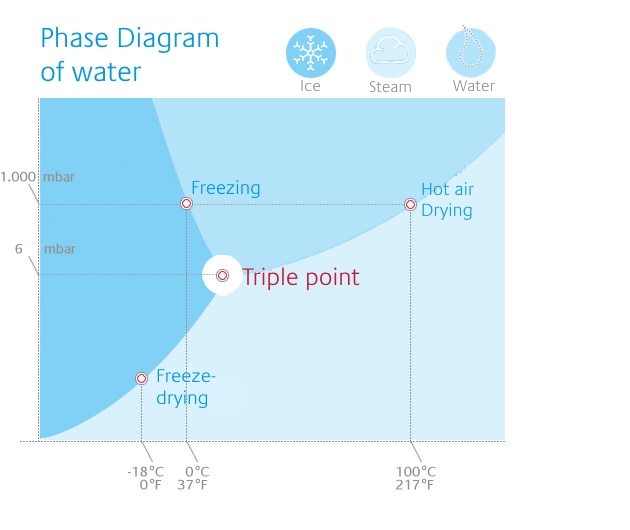

Freeze-drying—technically known as lyophilisation, lyophilization, or cryodesiccation—is a dehydration process typically used to preserve a perishable material or make the material more convenient for transport. Freeze-drying works by freezing the material and then reducing the surrounding pressure to allow the frozen water in the material to sublimate directly from the solid phase to the gas phase.

The 3 Steps of Freeze-Drying

- Freezing

To start the freeze-drying process, it is first necessary to freeze the raw material. At this stage, it is very important that the structure of the raw material remains unchanged and therefore products are quick frozen directly after harvesting at a temperature of -18°C (-0.4°F) - Main Drying

The second step of the process is the extraction of the water from the raw material. The IQF product is placed in a vacuum chamber. Under very low pressure, the frozen water contained in its structure is removed in the form of steam. This is called sublimation. To create sublimation, energy in the form of heat is needed. This energy can either be gained from the temperature difference between chamber and product or be supplied by built in heating systems. The drying chamber and the condenser area are kept under vacuum to support the migration of water vapor to the condenser where it is deposited in the form of ice, and to make sure that the vacuum is below the threshold required for sublimation. Freeze-drying starts to be possible at a temperature of 35°C (95°F). - Post Drying

After the free ice, has been removed by sublimation, the product still contains bound water which could affect shelf life and quality. During post-drying the most strongly bound water inside the product is converted into steam. This is a slow process. Post drying is called the third step, but begins during the main drying.